Vision CCD testing equipment

Product Features

It is an image sensor that can convert light into electric charge, and then convert it into digital signal through A/D converter for detection, detection of product accuracy, detection of appearance defects, size, 360-degree detection, weight detection, etc., CCD visual detection It is also required by the product itself to be tested, what are the test contents, and what are the requirements for efficiency and accuracy. The image signal obtained from the imaging system becomes the charge signal of the CCD, which completes the process of spatial discretization of the image. At the same time, the synchronizing signal, field synchronizing signal and fading signal required by the PAL system are generated on the CCD area array, and the complete video signal is synthesized and processed by the computer after output.

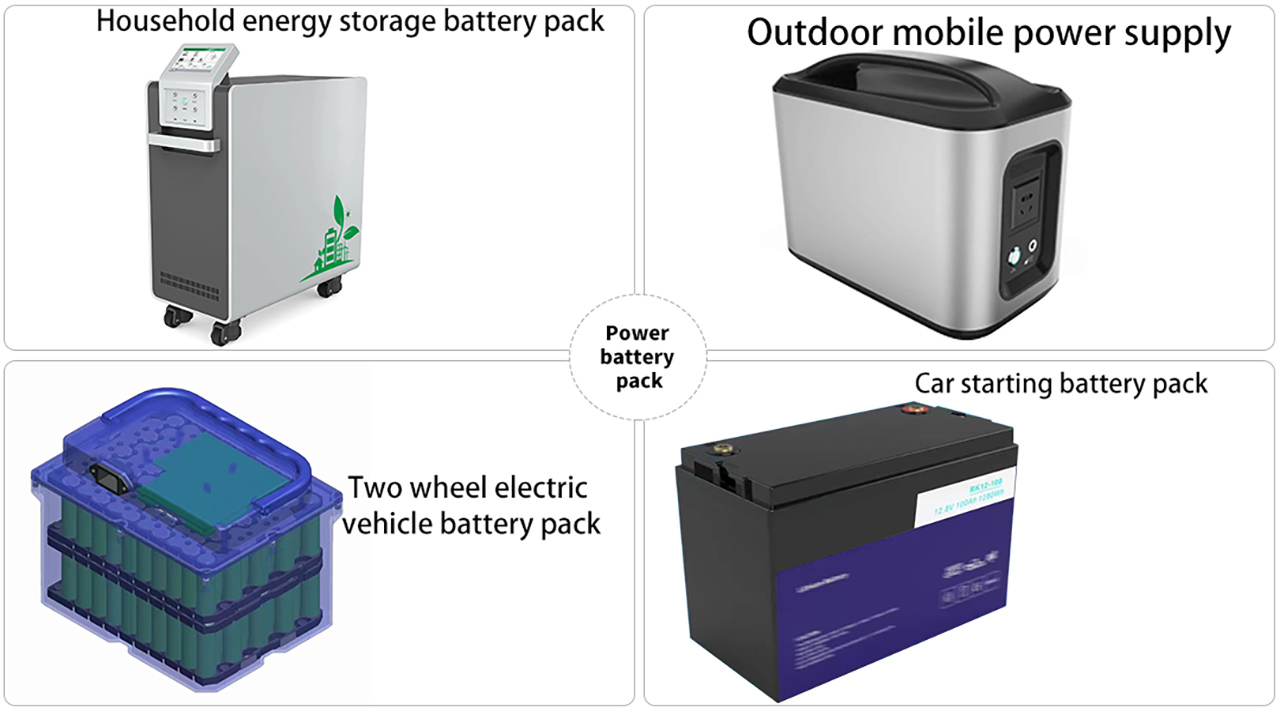

Application Areas

Is CCD visual inspection accurate?

In general, the manual inspection of products on the production line is definitely slower and less accuracy than visual inspection machine. The CCD visual inspection is used to analyze these signals and perform various operations to extract the characteristics of the target, and then control the on-site equipment system according to the results of the discrimination. . General CCD visual inspection is used in various industries such as industry, aerospace, heavy industry, electronic machinery, etc. CCD inspection equipment mainly uses machine vision inspection instead of human eye inspection, and the inspection speed is very fast. The detection efficient is very high.

After-sale service

Visual inspection involves taking an image of an object, inspecting it, and converting it into data for processing and analysis by the system to ensure compliance with the manufacturer's quality standards. Track and eliminate objects that do not meet quality standards. Most of the visual inspection and recognition currently on the market are semi-COMS, CCD and COMOS are still very different. According to the pixel distribution and information such as brightness and color, the appearance defects of the equipment are detected and converted into digital signals; the image system performs various operations on these signals to extract the characteristics of the target.